- Proof of Process

- Design for Manufacturability (DFM)

- Failure Mode and Effects Analysis (FMEA)

- Process Development

Industries Served

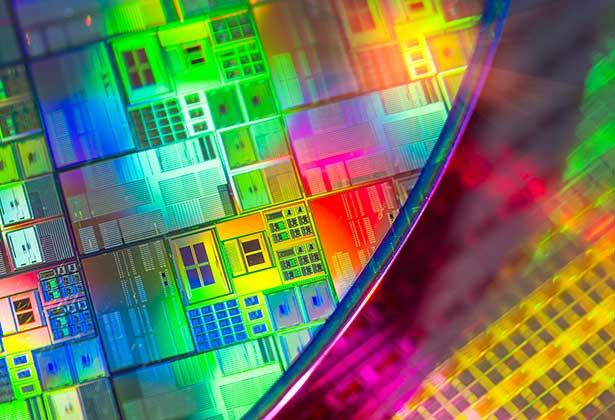

Electronics /Semiconductor

Electronics / semiconductor manufacturing is easily one of the most complex manufacturing environments. PMD is up to the challenge. From semi-automated vision inspection stations to state-of-the-art vision guided assembly robots, PMD has designed and built automation systems for high-speed assembly, as well as testing and inspection for electronic component and assembly manufacturing. With a seasoned controls department, PMD can integrate new systems with your existing network including MES/ERP systems.

AREAS OF EXPERTISE

Product Applications

PMD can supply all aspects of automation systems from turnkey production lines to lean cell manufacturing to pilot/prototype fixturing. Additionally, through the use of our simulation lab, PMD specializes in Proof-of-Process (POP) development to aid our customers in process solutions for new or unknown assembly/testing techniques.

- Wafer Handling

- Circuit Board Assembly & Test

- Electrical Connector Manufacturing

- Custom Automated Flow-Through Ovens

- Wire Bonder Integration

- High Precision Robotic Assembly

- Adhesive & Potting Compound Dispense & Curing

- Fiber Option Termination

- Cable Assembly & Termination

- RF Configuration

- Ink Tank Cartridge Filling Systems

- 300mm wafer pad shave

- Laser burn-in customized wafers

- Epoxy bonding of boards to heat sinks

- Wearables

- Vapor Deposition in High Vacuum

AREA OF EXPERTISE

Process Applications

- Adaptive Vision-Guided Robotics

- Metrology Systems

- End of Line (EOL) Testing

- Adaptive Assembly

- Leak Testing – HMS, Pressure Decay, Vacuum

- Adhesive Compound Dispense and Curing

- Laser Marking

- Integrated Oven Systems

AREAS OF EXPERTISE

Breadth of Capabilities

- URS Development

- Traceability Matrices

- SOP Development

- Validation

- FAT/SAT Protocol

- IQ, OQ, PQ

- CE Compliance

- Recipe Management

- High Volume Production

- Asynchronous / Synchronous

- Product Traceability

- World-Class OEE

- Optimized Engineering Process

- Filling & Dispensing Solutions

- 3rd Party Equipment Integration

- Incubation, Drying, & Curing

- Primary & Secondary Packaging Systems

- Robotics: Assembly, Inspection, & Material Handling

- Vision Inspection & Vision Guidance

- Assembly / Test

- Pilot Production

- Modularity / Flexibility

- Cleanrooms (ISO 7, Aseptic) & Design for Cleanability

- Explosion Proof (Class I Div I/II)

- Humidity Control

- Temperature Control

- ESD Control

- Other Challenging Environments

- New Model Variants

- Volume Adaptability

- High Mix Low Volume (HMLV)

- Strategic Partnerships

- Operator & Maintenance Training

- Machine Retrofits

- Spare Parts Programs

PMD

CAPABILITIES

PMD has the know how to leverage technology in manufacturing…

This is how time after time PMD has built success stories for our clients product launches, expansion initiatives and productivity enhancements.